SkySentry offers customized tether design, specification, and acquisition services. Professionals in the Lighter-than-Air industries realize that tethers critically impact mission success.

Power-fiber optic tethers.

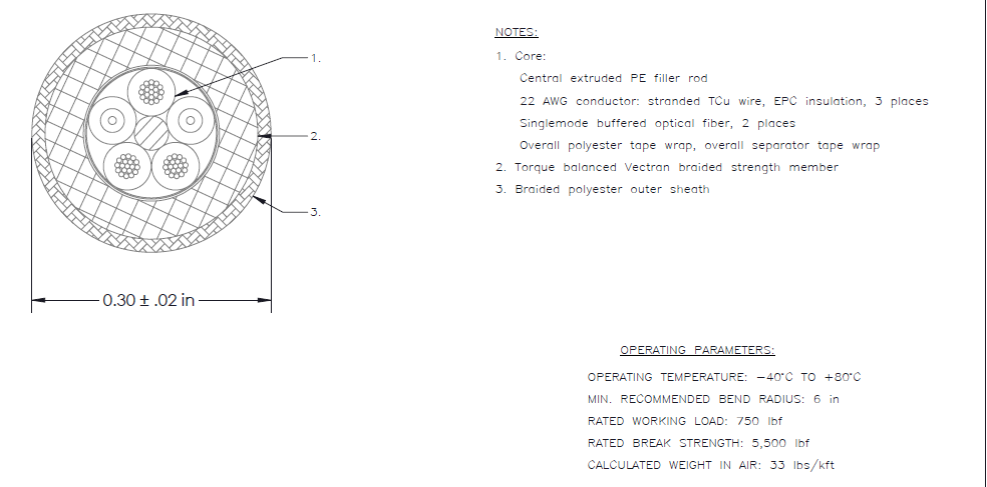

Numerous trade-offs must be considered when ordering a tether. It must be strong enough to securely attach the aerostat to the mooring station and prevent loss. It should be as light as possible, so as not to drive a need for a larger aerostat to lift it. In many cases, it should have copper wires to continuously power the payload on the aerostat. Likewise, tethers often have fiber optic strands to transmit data down from the aerostat, thus avoiding possible disruptions with  RF data links. To avoid breakage and excessive wear, the tethers must have a reasonable minimum bend rate, with an appropriate Working Load Limit and Minimum Breaking Strength. More subtly, designers must analyze the aerostat power system to ensure adequate power is delivered to the payload. This generally entails using the smallest wires possible, in consideration of the required amperage and impedance-driven voltage drop, to keep lifted weight as light as practical. You can see from this design drawing how the wires and fibers are packaged around the strength member, along with the protective outer coating, bend radius, lifted weight, etc. In general, these tethers are used for SkySentry’s Heavy Expeditionary and largest Tactically Expedient Aerostats. SkySentry is proud to have arguably the world’s premier tether design expert on staff to support its customers.

RF data links. To avoid breakage and excessive wear, the tethers must have a reasonable minimum bend rate, with an appropriate Working Load Limit and Minimum Breaking Strength. More subtly, designers must analyze the aerostat power system to ensure adequate power is delivered to the payload. This generally entails using the smallest wires possible, in consideration of the required amperage and impedance-driven voltage drop, to keep lifted weight as light as practical. You can see from this design drawing how the wires and fibers are packaged around the strength member, along with the protective outer coating, bend radius, lifted weight, etc. In general, these tethers are used for SkySentry’s Heavy Expeditionary and largest Tactically Expedient Aerostats. SkySentry is proud to have arguably the world’s premier tether design expert on staff to support its customers.

Synthetic tethers. For small aerostats, a reasonable alternative is to use synthetic tethers, which ultimately require the customer to fly batteries with the payload, as opposed to pushing power up the tether. Modern synthetic fibers are incredibly strong for their weight. As shown in the following  photo, many hundreds of feet can be put on small winches, without being concerned with minimum bend radius. The tradeoff in using synthetics is whether the customer’s concept of operations allows recovery of the aerostat each 8-12 hours to change

photo, many hundreds of feet can be put on small winches, without being concerned with minimum bend radius. The tradeoff in using synthetics is whether the customer’s concept of operations allows recovery of the aerostat each 8-12 hours to change

batteries.

Deciding on a tether.

Perhaps the largest factor in deciding on tether type is concept of operations, as mentioned above. Second is surely price. A customer needing power up the tether must anticipate a cost up to 7 times greater than synthetic, and the winch to handle the bend radius and connections at the bottom of the tether costs approximately 10 times more than the small electric winch. In any case, SkySentry specializes in helping customers walk through the considerations of buying right to make the mission successful.